5

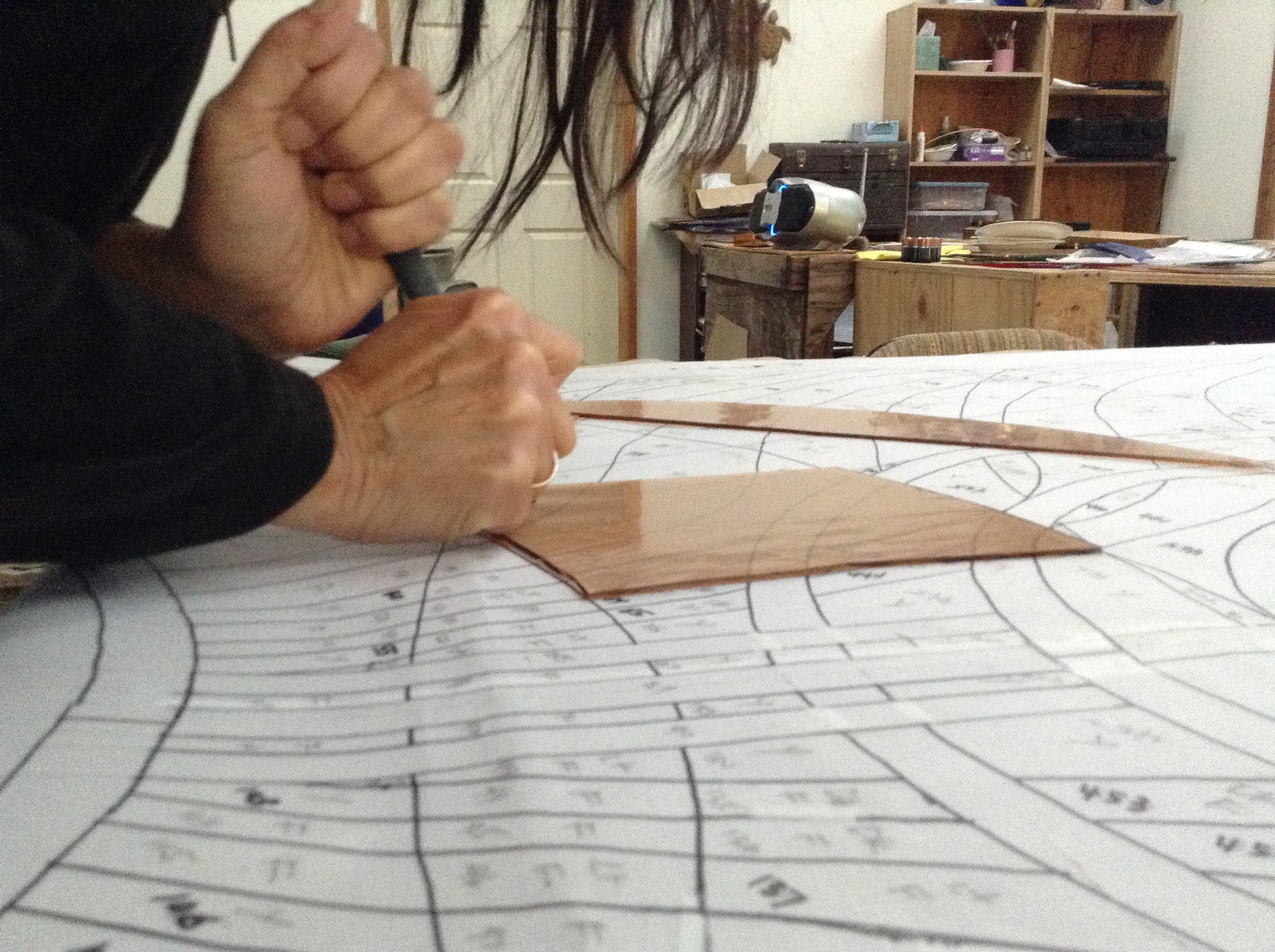

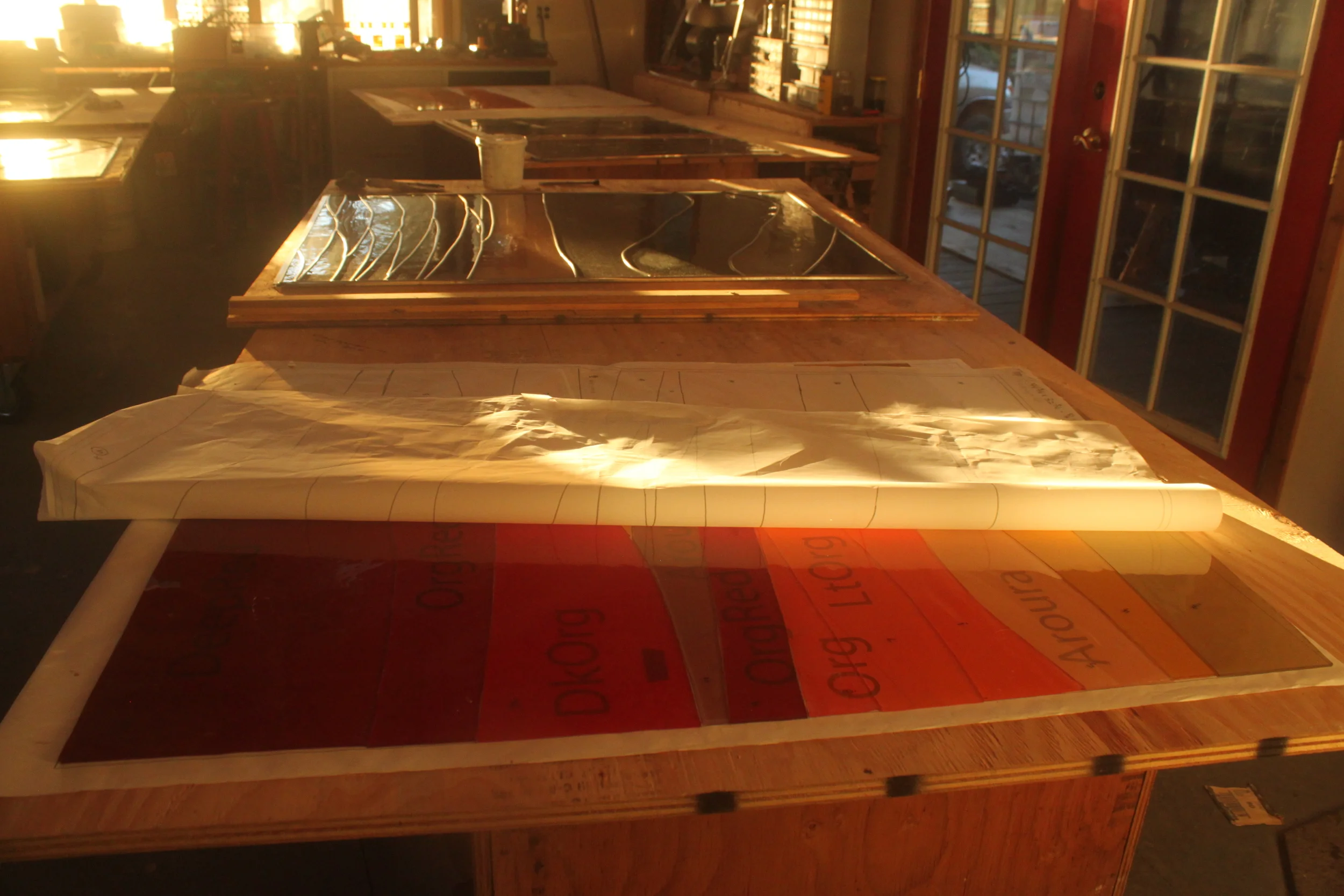

Making the pattern, choosing the glass.

5

Cutting the glass

6

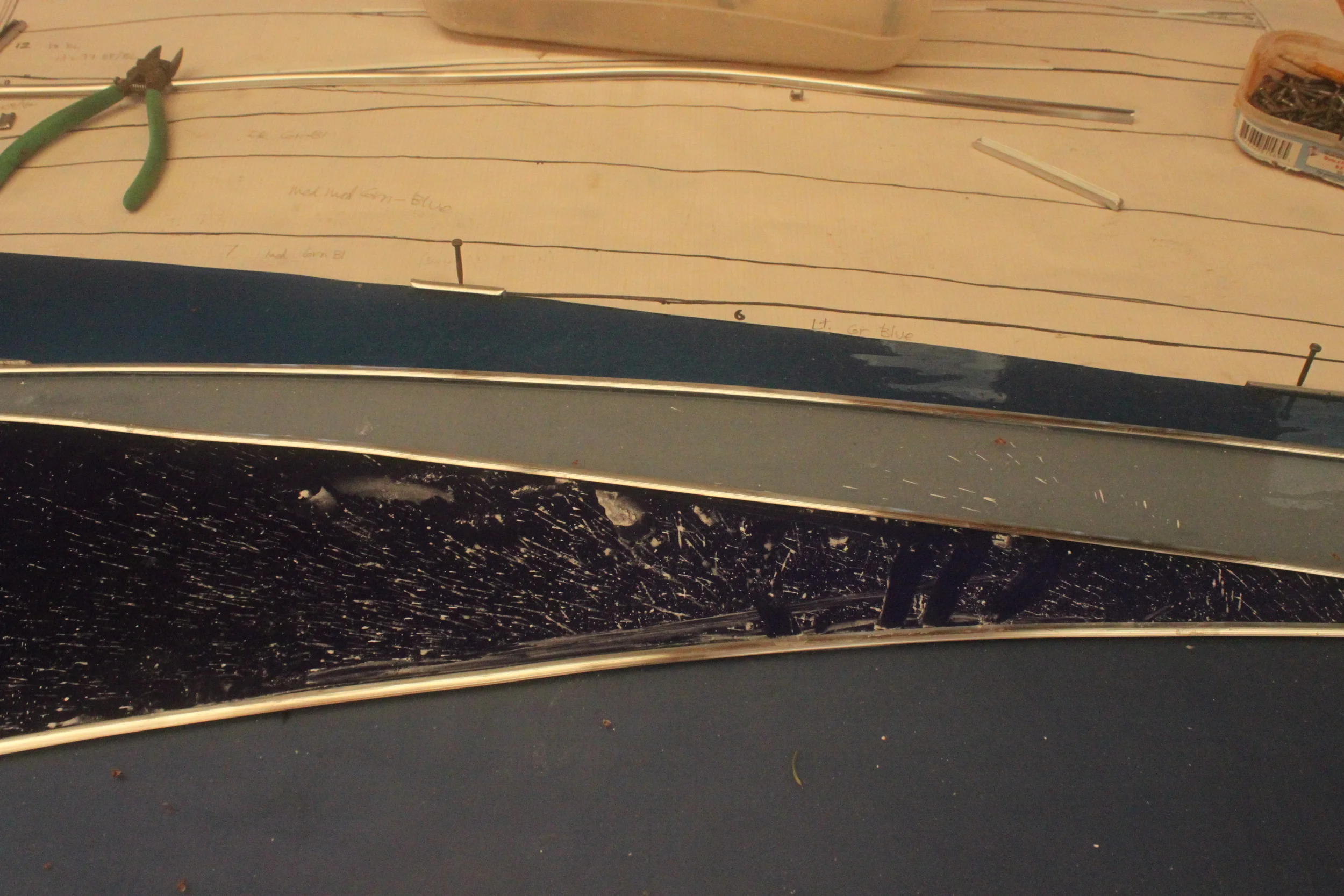

Glass cutting continues

6

Preparation of pieces for painting

2

Glass arrives

1

Final edits

2

Site Visit 6-30-15

1

Cutting the Resist

9

Silk Screening with Alan

5

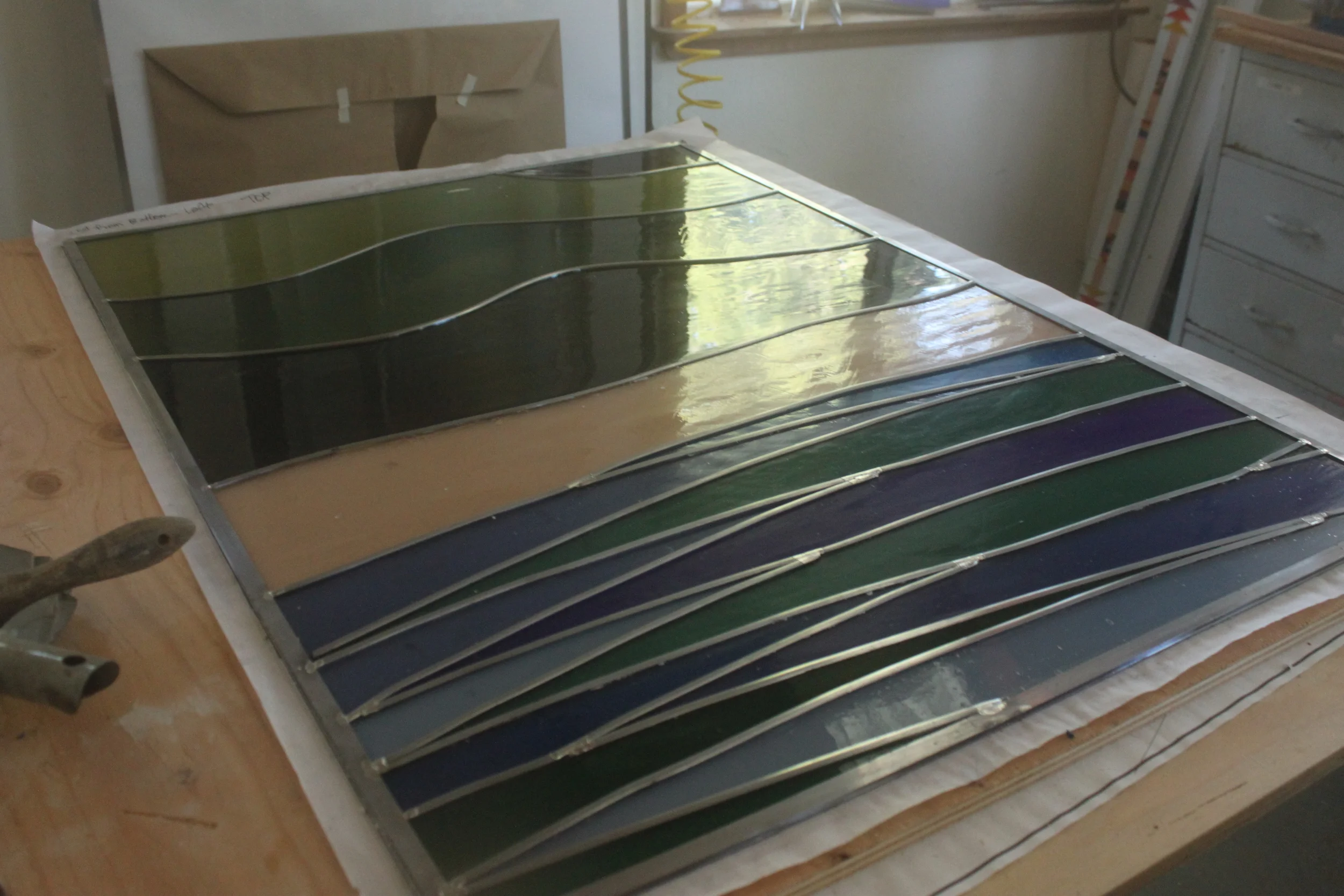

Assembly Begins

6

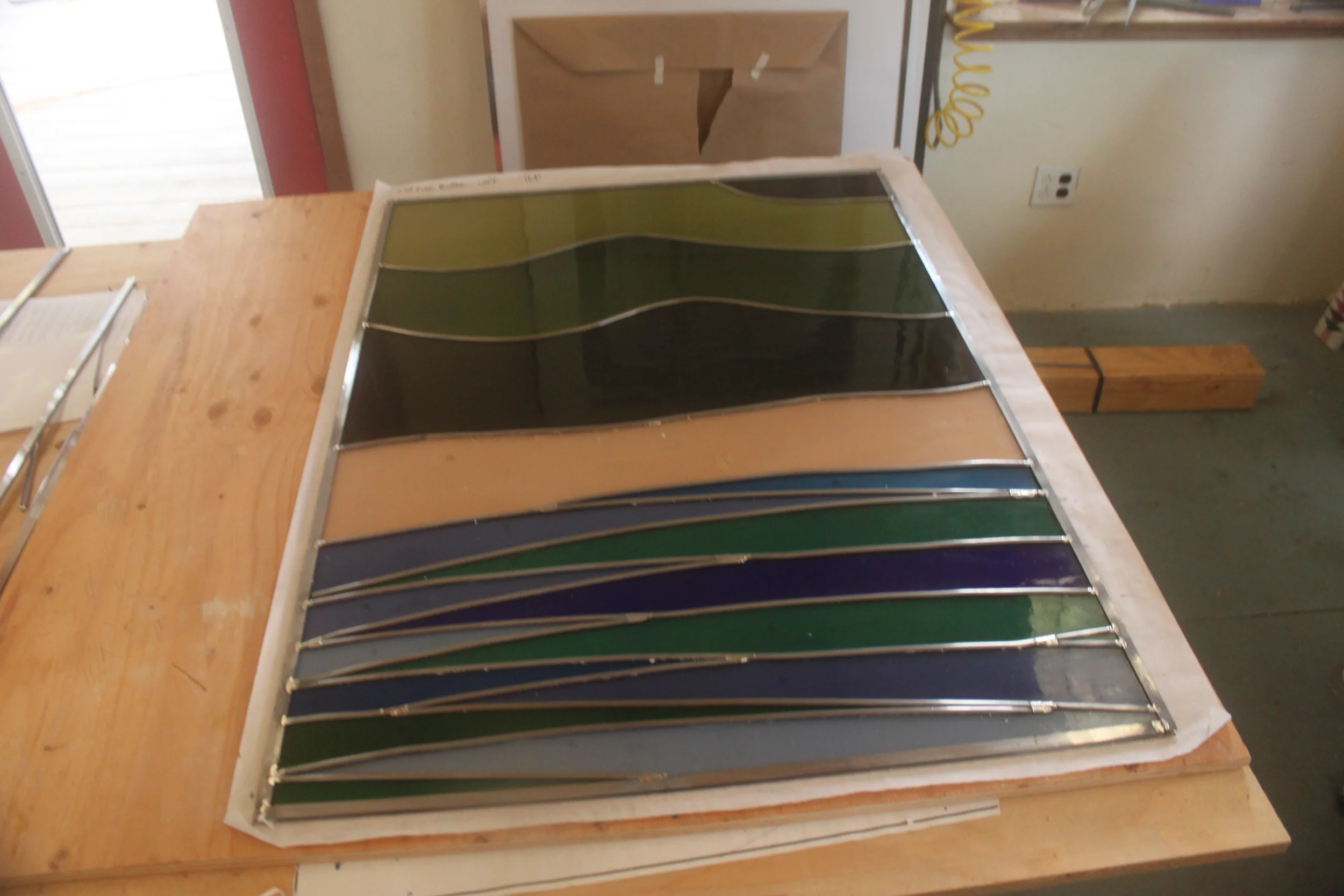

Assembly Continues

6

Assembly Continues

3

Assembly Complete

11

Soldering, Glazing and Cleaning

6

Reinforcement

7

Work Continues

4

Completion of the Holocaust Memorial

3

Work continues on the small Holocaust Memorial

10

Working on the Bima Windows

6

Work proceeds on the Bima Windows

5

Preparing for the Install

6

Bima Windows in Process

2

Delivery and Installation

1

Ner Tamid